Our expertise

Haffner Energy’s expertise has been forged over more than 32 years of experience.

32 years designing, developing and bringing to market a pioneering, patented technology that produces renewable energies with neutral-to-negative carbon footprint: biomass thermolysis.

Thermolysis

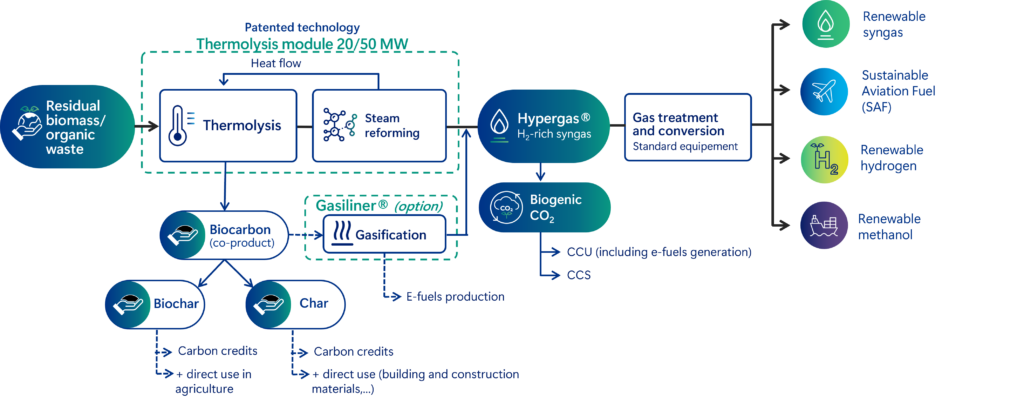

Thermolysis is a thermochemical process that results in the decomposition of biomass through heat (about 500°C). Two co-products derive from thermolysis:

- a solid carbon compound (biochar)

- thermolysis gases, composed of condensable (tars, oils, etc.) and non-condensable gaseous components (mainly dihydrogen – H2, carbon monoxide – CO, and carbon dioxide – CO2 )

The reaction is allothermic (external source of energy) and is performed in anaerobic conditions (absence of oxygen), which differentiate thermolysis from pyrolysis. A small part of the gas produced is used to supply the required energy to power the process: external energy sources such as electricity from the grid are not required.

Haffner Energy’s thermolysis process is a breakthrough technology protected by 15 patent families or more than 80 international patents. It is the result of over 30 years of experience converting biomass to energy, including 15 years of R&D.

Thermolysis is then combined with a reforming step that cracks molecules at very high temperatures (around 1000°C). The long-chain molecules of thermolysis gases are split into short molecules (mostly dihydrogen – H2, carbon monoxide – CO, carbon dioxide – CO2, methane – CH4). This stage is key for the destruction of tars, oils, and long carbon molecules produced at the thermolysis stage.

The thermolysis step combined with the reforming step produce a very energetic (around 15 MJ/kg) syngas (synthesis gas), rich in hydrogen, called Hypergas®. Both steps are built in a modular unit called the thermolysis module.

Gasification through Gasiliner®

For large projects where access to local and competitive biomass can become the limiting factor, gasifying the biochar in order to significantly increase Hypergas® production per unit of biomass can be of paramount importance.

Haffner Energy’s gasification process consists in gasifying the biochar, which means converting the solid carbon into hydrogen and carbon monoxide. This conversion is carried out at high temperatures (around 1000°C) with the addition of steam. Steam reacts with the carbon through the reaction C + H2O → H2 + CO.

Biochar, due to its considerable specific surface area, allows almost total conversion of coal, with ideal reaction kinetics. This translates into very high yields while reducing the ash to the inorganic fraction only.

Haffner Energy’s Gasiliner® differs from other known gasification technologies by being unaffected by low–temperature melting ashes, allowing the process to be biomass–agnostic.

Hypergas®

Hypergas® is the renewable hydrogen-rich syngas produced by Haffner Energy’s technology. Its high concentration in hydrogen (> 45% vol), which confers it a high heating value, and its low-impurities content sets it apart from standards syngases.

The quantity of Hypergas® produced depends on the Hypergas® Module range (from 10MW to 50MW). This Hypergas® Module is common to all our solutions. It is divided into:

- a thermolysis sub-unit

- a reforming sub-unit

- a purification sub-unit

- auxiliary equipment with instrumentation and regulation equipment

Once produced, Hypergas® can be then processed in different ways to:

- be used for industrial applications as a substitute to natural gas

- produce renewable hydrogen

- produce Sustainable Aviation Fuel (SAF)

- produce renewable methanol

Biomass

Haffner Energy has over 30 years of experience converting biomass to energy.

Haffner Energy’s process is notable for being biomass-agnostic. Biomass is an abundant commodity; it is also subject to strong seasonal and interannual variations, as well as to major availability differences depending on the region. Being biomass–agnostic considerably strengthens long-term security of feedstock supply, and significantly reduces costs. It also improves the chances of generating excellent societal acceptance of new projects, which is typically a challenge when using restrictive biomasses. Biomass and organic waste without recovery create value when used as feedstock for bioenergy, particularly for farmers. It is also an excellent way to stimulate the circular economy.

Our approach aims at creating value from biomass residues with no use competing uses (in compliance with RED III and with Annex IX of RED II), mainly from agriculture and organic wastes and residues such as:

- Cereal straws, silo waste

- Bagasse, beet pulp, olive pomace

- Short rotation coppice

- Vine residues and shoots

- Corn cobs

- Green Waste

- Biomass from regenerative crops on marginal lands (XanoGrass™, Miscanthus, Bamboo..)

- Biomass fraction of industrial waste not fit for use in the food or feed chain

- Algae (brown and green algae, sargassum….)

- Biomass fraction of wastes and residues from forestry and forest-based industries (bark, branches, pre-commercial thinning, leaves, needles, treetops, saw dust, cutter shavings)

- Manure

- Sewage sludge, paper mill sludge, digestates from biodigesters, etc.

- Organic Municipal Solid Waste (MSW) biomass fraction of mixed municipal waste

- Other non-food cellulosic material

The use of sustainable or biomass residues as a feedstock for energy production offers decisive benefits. It is an abundant and affordable resource that can be found in many places across the globe. The ubiquity of biomass thus allows the relocation of the entire energy production value chain, from the collection of feedstock to the final user, enhancing the energy and environmental transitions of territories as well as their energy sovereignty.

A biomass-to-energy expert, Haffner Energy has a clear and proven track record of ensuring that only sustainable biomass with no competing uses can be procured for our process. Our team boasts an extensive knowledge of the EU sustainability criteria related to the production of biogases, as mentioned in the article 29 of the EU Renewable Energy Directive. Biomass sustainability is also a concern in the USA, as mentioned in the 2016 Billion-Ton Report published by the US Office of Energy Efficiency & Renewable Energy.

Our Biomatch service was created with the purpose of supporting our customers in the sourcing of sustainable biomass for their projects. Haffner Energy is committed to making sure the agricultural feedstock is not competing with food uses, and not obtained from land with high-carbon stock or peatland. The same principle applies for forestry biomass, which should respect the hierarchy of use and be collected according to established sustainable forest management practices.

Biocarbon

Biocarbon is the solid co-product of biomass thermolysis. It is a carbon-rich material containing the biogenic carbon absorbed by plants from the atmosphere via photosynthesis. This characteristic makes it a major carbon sink, in particular when it is used as a soil amendment (it is known then as biochar). Or it can be gasified to increase clean fuels production.

Carbon sink

Biocarbon made from lignocellulosic biomass through Haffner Energy’s process is a powerful carbon sink: one ton of biochar (or char) can sequester about 3 tons of CO2eq. After compensating all emissions of production (manufacturing, transport and operating) it amounts to around 2 tons of CO2eq per ton of biochar.

More than 50 possible uses of biocarbon as a carbon sink have been identified to date. The most common and mature use is agricultural soil amendment (biochar) through direct application on fields or through incorporation to fertilizers. It can be a powerful lever of soil regeneration by significantly improving certain types of soils properties while storing carbon in soils over the long term. The water retention properties of biochar also create an effective natural flood barrier.

Biocarbon can also be incorporated into construction materials (char) such as asphalt or concrete, which allows road or building construction to feature a neutral carbon balance while improving thermal properties of materials.

Such carbon sequestration can entitle producers to receive Carbon Removal Certificates (CORC) that are tradable on the voluntary carbon market. Biochar produced by Haffner Energy’s technology can be eligible to the European Biochar Certificate which guarantees biochar quality.

Biochar (or char) has been identified by the IPCC as one of the most impactful solutions for combating climate change, with a potential to remove between 0.3 Gt and 6.6 Gt of CO2 per year (IPCC AR6, WGIII), due to its long-term carbon sequestration properties while offering multiple co-benefits

Gasification

Biocarbon is a very dense source of renewable energy (31 MJ/kg) that can be gasified on site to increase the production of biofuels such as SAF or renewable hydrogen. It can also be shipped to another site to be gasified, in particular to provide the biogenic carbon needed to produce e-fuels.

Carbon Credits (Carbon Removal Certificates)

To reach our climate goals (carbon neutrality by 2050), emissions-reduction efforts will need to be complemented by measures to remove carbon from the atmosphere.

Carbon removal consists in removing carbon dioxide from the atmosphere and sustainably storing it, with the goal of mitigating or reversing climate change. Also known as carbon dioxide removal (CDR), methods for carbon removal are often termed Negative Emissions Technologies (NETs).

There are several ways of doing this, with various degrees of storage permanence:

- Permanent storage (carbon is captured directly in the air and stored in a stable form)

- Carbon farming, meaning activities that increase carbon capture in soils and forests (for example forest restoration, peatland and wetland management)

- Carbon storage in products (for example carbon captured by trees is stored in wood-based constructions)

There is evidence that biochar, produced at pyrolysis temperature over 600°C, resembles inertinite and thus is highly stable. If produced under certain conditions, 97% of the total organic carbon in biochar is highly refractory carbon, i.e. carbon that has near infinite stability. This implies that biochar can have an extremely high permanence in terms of carbon dioxide storage.

This is why in 2022/2023, Biochar Carbon Removal accounted for 87-92% of all delivered carbon removals on the Voluntary Carbon Market. On this market, Carbon Removal Certificates (CORC) are turning carbon sequestration capability of the CO2 net-negative products into digital tradable assets.

Several private internationally recognized voluntary biochar standards and methodologies are already established for the purpose of CORC certification. Besides, the European Union is in the process of establishing an EU-wide certification scheme for carbon removals, opening the perspectives of Biochar Carbon Removal to be traded on a regulated market in Europe.

Biogenic CO2

Plants grow their biomass thanks to the carbon of the atmosphere; biomass is composed of a mixture of organic molecules containing 50% carbon in weight, hydrogen, oxygen, and small quantities of other atoms.

The carbon used to construct biomass is absorbed from the atmosphere as carbon dioxide (CO2) by plant life, using energy from the sun through photosynthesis. This is why we are talking of biogenic carbon, as opposed to anthropogenic carbon, of fossil origin.

Releasing biogenic carbon is neutral, thanks to the short carbon cycle; it does not cause any increase in the level of CO2 in the atmosphere unlike anthropogenic carbon. The carbon released is in fact the same carbon as that which was absorbed by the plant during its growth. The sustainable nature of the exploited biomass implies that this plant has been replaced by a new plant, and that the carbon stocks accumulated, for example in trees, are not exploited, except in the form of residues.

If the biogenic CO2 is not released, but sequestered (CCS or some CCU applications), then the thermolysis process becomes strongly carbon-negative, up to 23 kg of CO2 per kilo of hydrogen (in case of hydrogen production).

Clean fuels (biofuels and e-fuels such as methanol and Sustainable Aviation Fuels) production always requires a combination of hydrogen and CO2. Both molecules must be renewable for the fuels to be sustainable.

Biomass thermolysis enables the extraction of biogenic CO2 while producing renewable hydrogen.

- Part of the biogenic CO2 found within the composition of the Hypergas® is used in the production of SAF or methanol through the thermolysis process

- The surplus production can be used for e-fuels production (for example, each metric ton of bio-methanol produced through Haffner Energy’s process co-produces enough biogenic CO2 to produce approximately 1 ton of e-methanol.)

- The surplus can also be valued through other Carbone Capture and Utilization (CCU) applications requiring biogenic CO2 as a feedstock (agrifood, industry). It can also be geologically stored (Carbon Capture & Storage – CCS)

Technical expertise (EPCC or EPCM)

Feasibility studies

Engineering studies

Solution design

Integration

Procurement

Manufacturing

Assembly

Construction

Installation

Commissioning

Training

Performance trials

Process parameters optimization

Maintenance

Biomass and biochar expertise

- Preliminary feasibility stage : study of heat and mass balance

- Biomatch : support to secure sustainable biomass procurement and biochar offtake