Renewable hydrogen solution – HYNOCA®

Produce renewable hydrogen from local feedstock and with a neutral-to-negative carbon footprint

Achieve a competitive production price thanks to affordable feedstock and cost control (no dependance on the price of electricity)

Meet decarbonization targets and remove CO2 from the atmosphere thanks to a process with a neutral-to-negative carbon balance

Give value to local and sustainable feedstock and enhance the local value chain, with right-sized and on-site production

Renewable hydrogen simplified production process

Renewable hydrogen uses

Achieve a 99,97% v/v pure hydrogen suited for:

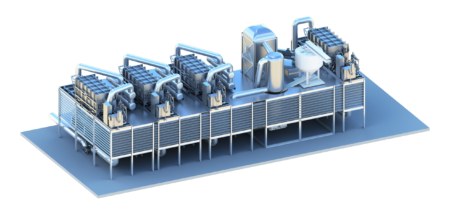

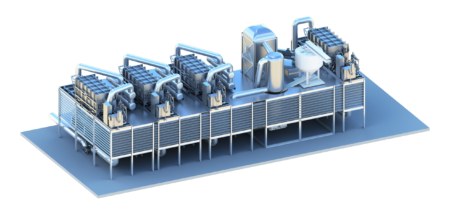

HYNOCA®: Turnkey solution for hydrogen production

HYNOCA® is a turnkey solution, from engineering to operation support, to produce renewable hydrogen without dependence on electricity.

Examples of module based on a 20-MW biomass inlet (50-MW biomass inlet capacity is also available):

(Thermolysis + Reforming)

Treatment, Enrichment, Purification and Compression (Included Water Gas Shift Reaction (WGSR) and Pressure Swing Adsorption (PSA))

(Thermolysis + Reforming + Biochar gasification)

Treatment, Enrichment, Purification and Compression (Included Water Gas Shift Reaction (WGSR) and Pressure Swing Adsorption (PSA))

- HYNOCA® 300 IB

- HYNOCA® 500 IG (with biochar gasification)

Technical expertise and support

- Feasibility, engineering, design

- Procurement, manufacturing, assembly

- Installation, commissioning, training and performance trials

- Biomass and biochar expertise Biomatch

HYNOCA® Flex 500 IG

HYNOCA® with biochar gasification to optimize syngas production, with the added option of electricity production whenever economically desirable. The goal is to reduce overall hydrogen production costs by providing flexibility with hydrogen offtakes and/or taking advantage of electricity pricing volatility.