Sustainable Aviation Fuel (SAF) solution – SAFNOCA®

Integrated solution to meet the challenges of Sustainable Aviation Fuel (SAF) production – through our patented biomass thermolysis technology

SAF’s contribution to air transport decarbonization

Aviation transportation accounts for 2.5% of the global carbon footprint. Its share is bound to increase as the industry grows while other sectors of the economy decarbonize faster. By 2050, SAF is estimated to contribute to aviation emissions reductions by up to 53%*, while improvements in technology, infrastructure, and operations will account for the rest.

Now and for the next 15 years, however, air transport decarbonization rests squarely and primarily on SAF. Indeed, SAF is a drop-in fuel, which means that it can be used by existing air fleets (air freight, private aviation, commercial aviation, military), with no changes to aircrafts or upgrades in infrastructure needed.

* Source: ATAG report 2021

SAF – the product

Sustainable Aviation Fuel is fuel made from non-fossil feedstocks.

SAF can be produced from a variety of different sources, including municipal solid waste, used cooking oils, biomass, as well as biogenic CO2 and renewable electricity (e-fuels, Power-to-Liquid).

SAF is blended with conventional (fossil) jet fuel at different levels. Up to 50% blending is authorized today, with no changes required to infrastructure or aircrafts.

SAF – the market

- 760,000 commercial flights have been operated using SAF*

- 69 airports currently regularly supply SAF (mostly in Europe and the U.S.)*

- 50 airlines have committed to 2030 SAF goals ranging from 5% to 30% of their total fuel usage, with most of them committing to 10% use*

- $45 bn in current forward purchase agreements for SAF by airlines, operators and corporate partners (compared to $6 billion pre-Covid)*

- 5.6 million tonnes (7 billion litres) of the total aviation fuel supply (about 2%) could be fulfilled using SAF by 2025, increasing to around 6-10% of supply by 2030 (without further policy measures)

*ATAG’s latest data as of July 2024

SAFNOCA®: the missing link to converting organic waste into SAF

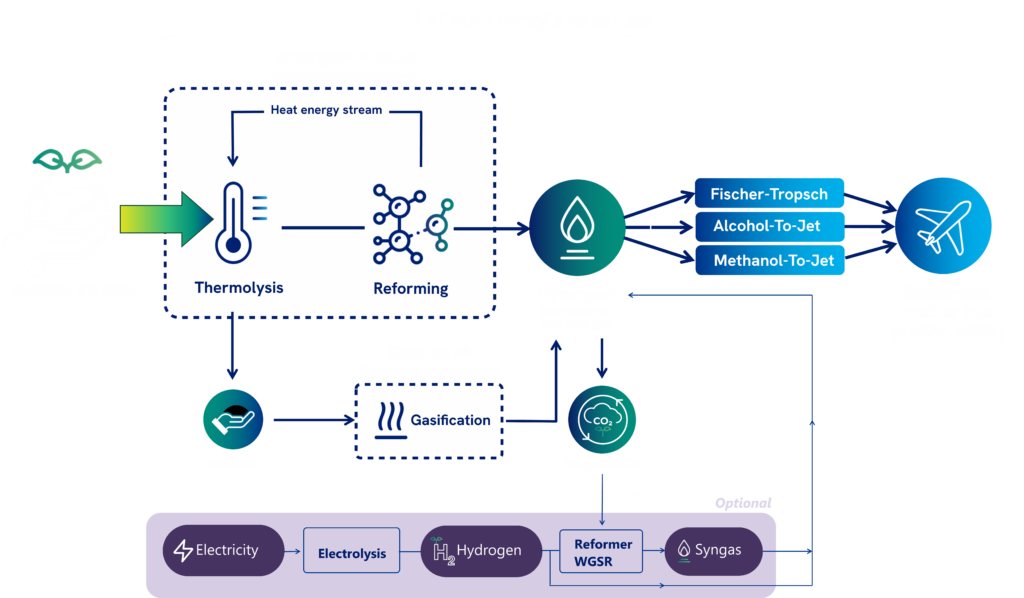

SAFNOCA® overcomes the barriers to large-scale SAF production. Built on our 30 years of experience converting all types of residual biomass and organic waste to energy, our patented thermolysis technology allows the conversion of any solid biomass residues or wastes into Hypergas®. This hydrogen-rich syngas is immediately available to process through the Alcohol-to-Jet (ATJ) or Fischer-Tropsch pathway.

In addition, producing bio-SAF through biomass thermolysis generates biogenic CO2, which can be used to co-produce e-SAF.

SAF production always requires hydrogen and biogenic carbon, which are organically found within Hypergas® composition in the right proportion – compliant with several ASTM SAF pathways

Proprietary technology efficient in converting all types of sustainable and / or residual biomass, regardless of seasonal variations, guaranteeing security of supply to enable massive scale-up.

Our process virtually features a neutral carbon footprint in a full life-cycle analysis: reduction of the SAF CO2 eq emissions by over 90% compared to fossil kerosene